Advantages of Hemlock

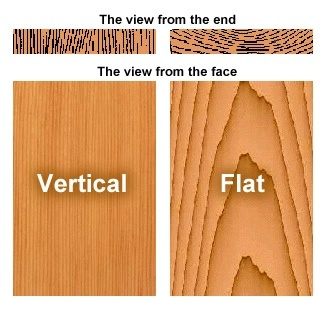

Vertical Grain vs Flat Grain Lumber

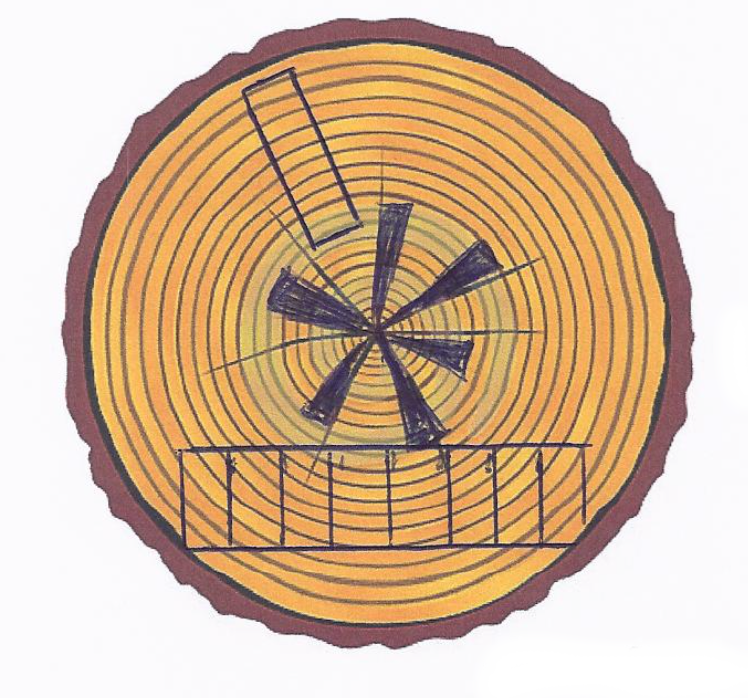

Where does Vertical Grain or Flat Grain come from in a log?

The pictures to the left illustrate where vertical grain and flat grain comes from. It takes a much larger, higher grade log to produce a vertical grain clear piece than it does to produce a flat grain clear piece. The depth of clear in each log determines the maximum width of a piece of vertical grain clear. A smaller log with shallow clear would only produce flat grain clear.

Annual Growth Rings

The annual growth rings of wood are composed of soft porous wood (spring wood) that grows in early spring and relatively harder dense wood that grows in late summer (summer wood). It is the darker summer wood that we count as the “growth rings”. The softer spring wood wears more quickly in abrasive applications such as flooring, decking, or siding. Since vertical grain lumber exposes more a minimum of this soft spring wood, it lasts longer. The softer spring wood is also subject to a faster degradation from the sun’s ultraviolet rays. The UV rays actually destroy the wood cell structure and this creates pockets that retain dirt and moisture. The presence of moisture can lead to biodegradation or rotting of the wood.

Shrinking and Expanding

Wood shrinks and expands with changes in moisture content. in exterior applications these changes are severe. The purpose of all finishes (paints/stains etc.) is to protect wood from the re-absorption of moisture and the damaging affects of the sun’s UV rays. This can lead to the premature decay of the wood and the expense of replacement. Pains and solid colour stains offer the best protection from these elements.

Paints and Stains (“Finishes”)

Vertical grain lumber holds paint and stain much better and does not stress the finish like flat grain lumber. All finishes have limited elasticity and anything that reduces the movement of the wood translates into a longer lasting finish. The softer spring wood absorbs paints and stains much more than the summer wood. The paint or stain finishes actually form a bridge over the denser summer wood. On vertical grain lumber, these bridges are much shorter and thus much stronger than on flat gain lumber. The benefit of using a vertical grain lumber is that in the long run you won’t have to re-apply finishes as often and in addition, there is much less surface preparation resulting in less maintenance cost overall. Some species of vertical grain lumber are known to last over 100 years.

Flat Grain Lumber

Flat grain lumber is manufactured where the annual growth rings run roughly parallel to the face of the board. As shown in the illustration, they tend to shrink across the width and cup. This will ultimately cause splitting which allows moisture and dirt to enter the wood ultimately resulting in decay. As well, if the lumber doesn’t remain stable, paints tend to peel off the surface increasing maintenance costs.

Vertical Grain Lumber

Edge or vertical grain lumber produces a “vertical grain” where the annual growth rings are vertical to the face of the board. As shown in the illustration, they tend to shrink across the the thickness and remain stable with no cupping. Vertical grain has much better wearing properties as the denser summer wood (dark rings) are closer together protecting the softer (spring wood).

Advantages of Vertical Grain Clear Lumber

- Durability - Stands up to the exterior elements

- Less shrinkage

- Less cup and twist. The shape of lumber remains much more stable than flat grain

- Less raised grain than flat grain lumber

- Less tendency to check

- Better wearing properties in all applications

- Retains paints and stains much longer without peeling

- Superior appearance in high end applications

- Will perform much longer with lower maintenance costs

Disadvantages of Flat Grain Clear Lumber

- Will cup and warp with changes in moisture content

- Splits or checks easily allowing moisture to penetrate

- Paint and stain will peel off as the piece cups

- Although it’s cheaper up front, the long term maintenance costs are much higher than vertical grain lumber